Value Valves Co., Ltd. has established itself as a leader in the valve manufacturing industry, underpinned by a commitment to quality and reliability. This article delves into the company’s rigorous testing procedures, which are a cornerstone of their reputation for high-quality products.

40 Years of Experience and Research

With over 40 years of experience, Value Valves has developed a deep understanding of valve technology and its applications. The company employs a dedicated team of analysts and researchers who ensure the accuracy and consistency of data across all their valve products. This long-term commitment to research and development underlies their ability to meet diverse industrial needs and maintain a competitive edge in technology.

Comprehensive Testing Procedures

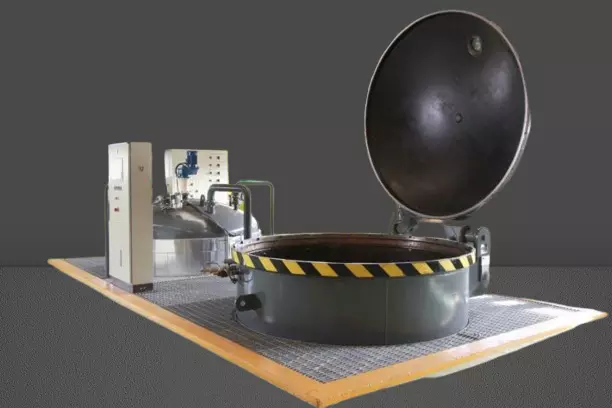

Value Valves has implemented a wide range of testing procedures to ensure the highest quality of their products. They have self-developed high-quality rubber valve seats tailored to specific applications. The company’s testing repertoire includes fire-safe tests, cryogenic tests, low emission testing, and life cycle tests, all conducted in their factory lab. Additionally, they offer Oil Restriction treatment in a clean room, and their disc and fluid pipes can be polished according to the required cleanliness level.

Certifications and Standards Compliance

The company’s commitment to quality is further evidenced by its adherence to various international standards and certifications. Value Valves has received numerous certifications, including:

- ISO 9001:2008

- PED(H)

- ATEX

- Fire Test Certification

- ISO 15848-1 CO1~CO3 FET

- BS 6364 Cryogenic Test

- IEC 61508-1 SIL 3

These certifications, issued by organizations such as TUV-Rheinland, MIRDC-Metals Industry Research and Development Center, and Lloyd’s Register, demonstrate the company’s compliance with rigorous international standards. Moreover, they have received certificates from ABS-American Bureau of Shipping, API-American Petroleum Institute, CR-China Corporation Register of Shipping, BV-Bureau Veritas, NK-Nippon Kaiji Kyokai, DNV-Det Norske Veritas, TSG, SGS, CRN, and UL.

Call to Action

For those interested in integrating Value Valves’ high-quality, rigorously tested products into their systems, contacting EAS, an authorized distributor, is the first step. EAS offers expert guidance and support to ensure that you select the right products for your specific needs. Reach out to EAS today to learn more about how Value Valves can enhance your operations with their top-of-the-line valve solutions.

Conclusion

Value Valves’ comprehensive approach to quality assurance, rooted in decades of experience, rigorous testing procedures, and adherence to international standards, positions them as a reliable and innovative leader in the valve manufacturing industry. Their commitment to quality not only meets but often exceeds the expectations of their diverse clientele, ensuring the reliability and safety of their products in various industrial applications.