Introduction: Embracing a Greener Future in Electric Motor Maintenance

In the ever-evolving landscape of industrial machinery, the emphasis on sustainability has become paramount. Electric motors, the heart of numerous industrial applications, are no exception. The maintenance practices of these motors, specifically rewinding and overhauling, play a critical role in enhancing their efficiency and longevity, ultimately contributing to a greener industrial environment.

Understanding Electric Motor Efficiency: The Core of Sustainability

The Impact of Electric Motors in Industry

Electric motors are ubiquitous in the industrial sector, powering everything from small machinery to large manufacturing units. Their efficiency directly influences energy consumption and operational costs, making their maintenance a high priority.

The Role of Maintenance in Motor Efficiency

Regular maintenance, including rewinding and overhauling, ensures that electric motors operate at their optimum efficiency. This not only reduces energy consumption but also extends the life of the motor, thereby reducing waste and the need for new motor production.

Rewinding: A Closer Look at the Process and Benefits

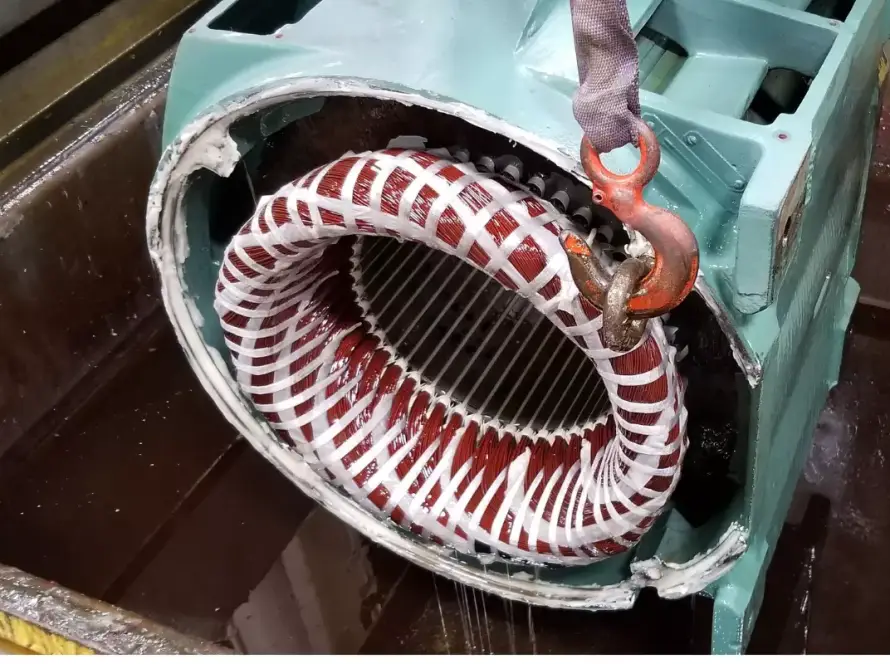

What is Motor Rewinding?

Motor rewinding involves replacing the coil windings on the motor’s stator or rotor. This process is essential when windings are damaged due to overheating, wear, or electrical surges.

Sustainability Benefits of Rewinding

By rewinding motors, companies can significantly extend the motor’s life, reducing the need for manufacturing new motors and thereby conserving raw materials and energy. It also prevents the disposal of motors, minimizing environmental pollution.

Overhauling for Enhanced Performance and Longevity

Understanding Motor Overhauling

Overhauling refers to the comprehensive inspection and repair of an electric motor. It includes checking all components, from bearings to windings, and repairing or replacing parts as necessary.

Sustainability Advantages of Overhauling

Through overhauling, motors are restored to their optimal condition, improving efficiency and reducing the likelihood of unexpected breakdowns. This process enhances the sustainability of motors by prolonging their operational life.

Advanced Technologies in Motor Maintenance

The Integration of IoT and Predictive Maintenance

The advent of IoT (Internet of Things) in industrial maintenance has revolutionized how motor efficiency is monitored and maintained. Predictive maintenance, using IoT sensors, can preemptively identify issues before they lead to motor failure.

Energy-Efficient Materials and Practices

The use of energy-efficient materials in motor components, such as improved insulation and conductive materials in windings, plays a significant role in enhancing motor efficiency and sustainability.

Case Studies: Success Stories in Sustainable Motor Maintenance

Real-World Examples of Effective Rewinding and Overhauling

Several industry leaders have successfully implemented sustainable motor maintenance practices, leading to significant energy savings and reduced carbon footprints.

Regulatory Compliance and Industry Standards

Navigating the Complex Landscape of Industry Regulations

Adhering to industry standards and regulations is crucial in motor maintenance. These guidelines ensure that maintenance practices meet the necessary quality and environmental standards.

Challenges and Solutions in Sustainable Motor Maintenance

Overcoming Common Hurdles

While the transition to sustainable practices presents challenges, such as initial costs and training requirements, the long-term benefits outweigh these temporary obstacles.

Conclusion: The Path Forward in Sustainable Electric Motor Maintenance

In conclusion, the adoption of sustainable practices in electric motor maintenance, particularly through rewinding and overhauling, is not just a step towards environmental responsibility but also a strategic move for operational efficiency and cost savings. Embracing these practices is essential for any forward-thinking industry player.

FAQs

- What is the most significant benefit of rewinding electric motors? Rewinding extends the life of motors, reducing environmental impact and manufacturing demands.

- How does overhauling contribute to sustainability? Overhauling improves efficiency and prolongs motor life, reducing waste and energy consumption.

- What role does IoT play in motor maintenance? IoT enables predictive maintenance, preventing breakdowns and optimizing efficiency.

- Are there specific regulations governing motor rewinding and overhauling? Yes, various industry standards ensure these practices meet quality and environmental criteria.

- What is the biggest challenge in adopting sustainable motor maintenance practices? The initial investment and the need for specialized training are the primary challenges.

Contact EAS for Industry-Compliant and High-Quality Supplies and Repair Kits

EAS is your go-to source for top-tier electric motor maintenance solutions. Committed to upholding industry standards, we offer an extensive range of supplies and repair kits to ensure your operations are not only efficient but also environmentally responsible. Get in touch with us to enhance your sustainability efforts in electric motor maintenance.