Introduction:

In the world of electric motor maintenance, the significance of electrical varnishes is often underestimated. These varnishes are vital for protecting motor components from environmental factors, electrical stresses, and mechanical wear. This article delves into why quality electrical varnishes are essential for maintaining the longevity and efficiency of electric motors.

Understanding Electrical Varnishes:

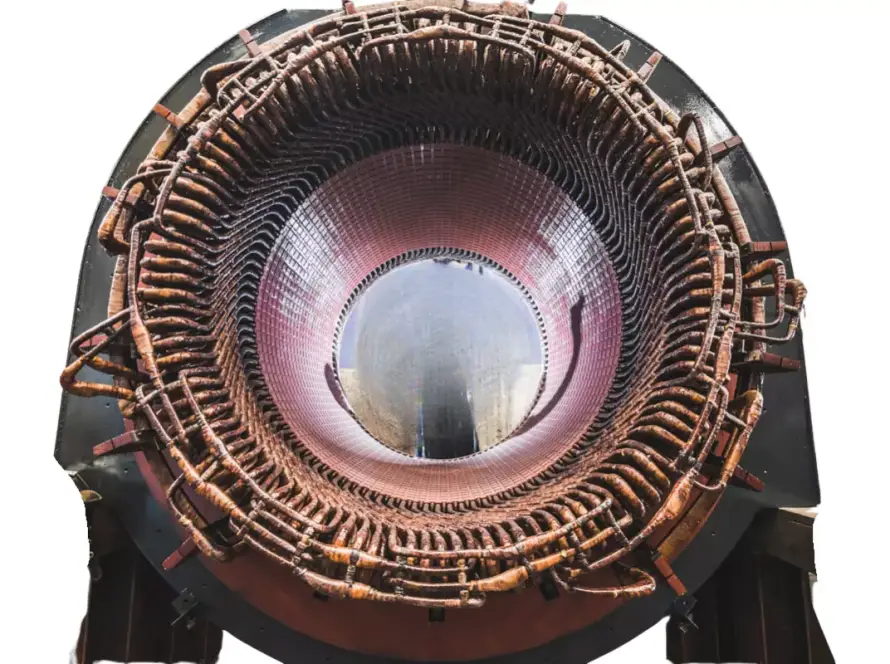

Electrical varnishes are specialized coatings applied to electric motor components. They provide insulation, protect against moisture and contaminants, and enhance thermal properties. The quality of these varnishes directly impacts the motor’s performance and lifespan.

Protection Against Environmental Factors:

- Moisture Resistance: High-quality varnishes create a barrier against moisture, which can cause corrosion and electrical failures.

- Dust and Contaminant Shield: Motors operate in various environments, and varnishes help shield sensitive components from dust and contaminants.

Enhancing Electrical Insulation:

Quality varnishes improve the insulation properties of motor windings. This is crucial for preventing electrical shorts and ensuring safe operation, especially in high-voltage scenarios.

Thermal Management and Heat Dissipation:

Effective heat dissipation is essential for motor efficiency and durability. Electrical varnishes enhance the thermal management of motors by aiding in heat distribution and preventing overheating.

Extending Motor Life:

- Preventing Wear and Tear: Regular application of quality varnish can significantly reduce the wear and tear on motor components, thus extending the motor’s life.

- Reducing Maintenance Costs: With better protection, motors require less frequent repairs, saving on maintenance costs over time.

Choosing the Right Varnish:

Selecting the appropriate varnish involves considering the motor’s operating environment, temperature range, and electrical requirements. The article provides guidance on how to choose the right varnish for specific applications.

Application Techniques:

Proper application of electrical varnishes is as important as the varnish quality itself. The article offers insights into best practices for varnish application, ensuring maximum protection and efficiency.

Case Studies:

Highlighting real-world examples where high-quality electrical varnishes have made a significant difference in motor maintenance, enhancing performance, and reducing downtime.

Conclusion:

Quality electrical varnishes play a pivotal role in electric motor maintenance. By providing protection, improving insulation, aiding in thermal management, and extending motor life, they are an indispensable part of motor care. Regular maintenance with the right varnishes is key to ensuring motor efficiency and longevity.

For more information on selecting and applying quality electrical varnishes, contact our expert team for personalized advice. Protect your motors with the best – choose quality, choose efficiency.