Introduction: High voltage coil manufacturing is a cornerstone of the electrical industry, critical for applications ranging from power generation to transportation. The sector is evolving rapidly, with new trends and techniques emerging to meet the demands of modern technology. This article explores the latest advancements in high voltage coil manufacturing, shedding light on how these developments are shaping the future of the industry.

Emerging Trends in High Voltage Coil Manufacturing: The high voltage coil manufacturing industry is witnessing several key trends:

- Material Innovation: There has been a significant shift in the materials used for high voltage coils. Manufacturers are increasingly turning to novel insulating materials that offer better thermal stability and electrical properties. These materials not only enhance the performance of the coils but also contribute to their longevity.

- Automation in Manufacturing: Automation is transforming high voltage coil production. Automated winding, insulation, and testing processes have led to increased efficiency, consistency, and safety in manufacturing. This shift is particularly crucial in meeting the high standards required for high voltage applications.

- Customization and Flexibility: With the diversification of electrical and electronic applications, there is a growing need for customized coil solutions. Manufacturers are now offering more flexible design and production services to cater to specific customer requirements, ranging from unique sizes to specialized performance characteristics.

Advanced Techniques in Coil Manufacturing: In addition to these trends, several advanced techniques are becoming standard in the industry:

- Precision Winding Techniques: The accuracy of winding techniques has a significant impact on the performance of high voltage coils. Advanced precision winding methods ensure uniformity and optimal distribution of wire, which is critical for the efficiency and reliability of the coils.

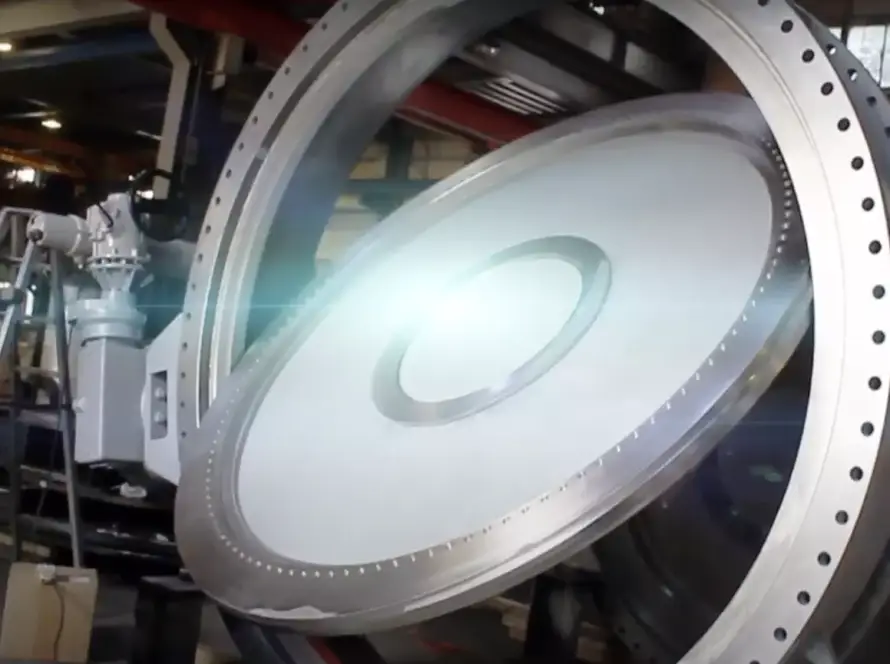

- Improved Insulation Methods: The quality of insulation in high voltage coils is paramount. Manufacturers are employing improved insulation techniques, such as Vacuum Pressure Impregnation (VPI), which offers superior insulation quality and protection against environmental factors.

- Enhanced Testing Protocols: High voltage coils undergo rigorous testing to ensure their reliability and safety. Enhanced testing protocols, including thermal cycling and dielectric tests, are now integral to the manufacturing process, providing an additional layer of quality assurance.

Sustainability in Coil Manufacturing: Sustainability is increasingly becoming a focus in high voltage coil manufacturing. Manufacturers are exploring ways to reduce environmental impact through eco-friendly materials and energy-efficient production processes. This shift not only addresses environmental concerns but also resonates with the growing demand for sustainable products in the market.

Challenges and Solutions: Despite these advancements, the high voltage coil manufacturing industry faces several challenges:

- Meeting Diverse Industry Standards: High voltage coils are used in a variety of industries, each with its own set of standards and requirements. Manufacturers must navigate these diverse standards to ensure compliance and relevance in different markets.

- Balancing Cost and Quality: Maintaining the balance between cost-effectiveness and high-quality production is a constant challenge. Innovations in materials and processes are critical in addressing this challenge, ensuring that manufacturers can provide high-quality coils at competitive prices.

Conclusion: The high voltage coil manufacturing industry is at an exciting juncture, with emerging trends and advanced techniques driving its evolution. From material innovation to sustainability, the industry is adapting to meet the changing needs of modern technology. As manufacturers continue to embrace these advancements, the future of high voltage coil manufacturing looks poised for further growth and innovation.

To keep up with the latest in high voltage coil manufacturing, stay connected with industry updates and innovations. Whether you’re a manufacturer, a business in the electrical sector, or an enthusiast, understanding these trends and techniques is crucial for navigating the future of electrical technology.