Introduction: Vacuum Pressure Impregnation (VPI) is a pivotal technology in the electric motor industry, revolutionizing how motor components are insulated and protected. This article delves into the intricacies of VPI, exploring how this process enhances motor performance, durability, and overall efficiency.

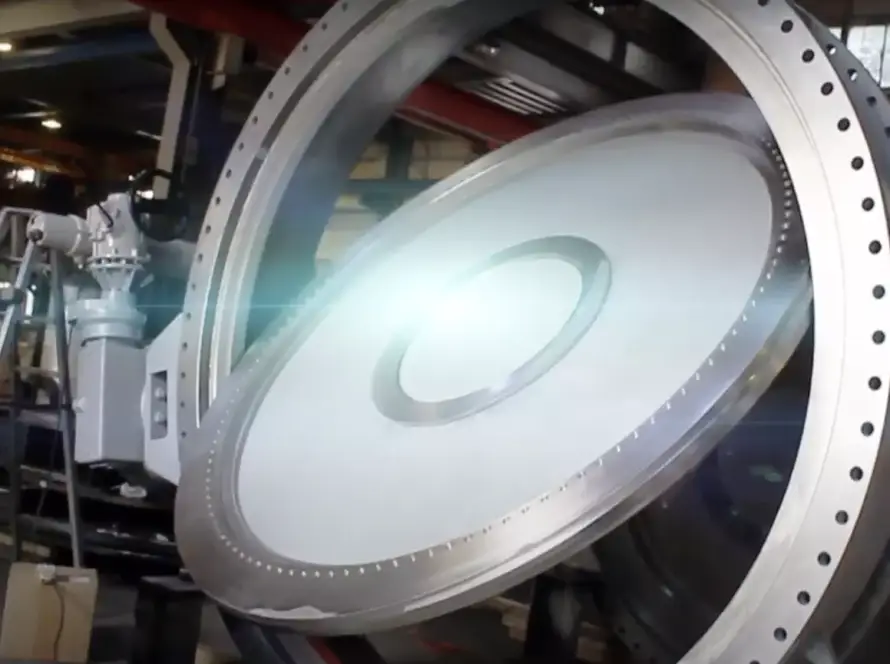

The VPI Process: At its core, VPI is a method used to apply insulating resin to electric motor windings. The process involves submerging the motor components in a resin bath and then applying vacuum and pressure. This combination ensures that the resin permeates deeply into the winding’s intricate spaces, creating a uniform and robust insulation layer.

Enhanced Insulation Quality: One of the primary benefits of VPI is the exceptional insulation quality it offers. By thoroughly impregnating the windings, VPI creates a solid, void-free insulation layer. This enhanced insulation significantly reduces the risk of electrical failures, such as short circuits, which are crucial for the motor’s reliability and safety.

Improved Thermal Management: VPI also plays a vital role in thermal management. The uniform insulation layer achieved through this process helps in the effective dissipation of heat. Motors treated with VPI can operate at higher temperatures without the risk of insulation breakdown, making them suitable for demanding applications.

Increased Mechanical Strength and Environmental Resistance: The resin impregnation via VPI adds to the mechanical strength of the windings. This increase in strength makes the motor more resistant to vibrations and mechanical stresses. Additionally, the resin layer provides excellent resistance to moisture, chemicals, and other environmental factors, further extending the motor’s life in harsh operating conditions.

Customizability and Versatility: VPI technology is highly adaptable, allowing for customization based on the specific needs of different motor applications. Various resins can be used in the VPI process, each offering different properties to cater to specific environmental, thermal, and electrical requirements.

Cost-Effectiveness and Longevity: While VPI might represent a higher initial investment, its impact on the motor’s longevity and reduced maintenance needs make it a cost-effective solution in the long run. Motors treated with VPI exhibit extended lifespans and lower failure rates, translating into cost savings over time.

The Role of VPI in Advanced Motor Applications: In high-performance and specialized motor applications, such as those in electric vehicles or industrial machinery, the advantages of VPI become even more pronounced. The reliability, thermal efficiency, and enhanced insulation properties provided by VPI are essential for these advanced applications.

Challenges and Considerations in VPI Implementation: Implementing VPI technology does come with its challenges. The process requires specialized equipment and expertise. Additionally, selecting the appropriate resin and optimizing the impregnation process for different motor designs are crucial considerations for achieving the desired outcomes.

Conclusion: Vacuum Pressure Impregnation stands as a key enabler in the pursuit of more efficient, reliable, and durable electric motors. Through its superior insulation quality, thermal management capabilities, and enhanced mechanical strength, VPI is integral to the advancement of modern motor technology. As the electric motor industry continues to evolve, the role of VPI in achieving high-performance motor solutions becomes increasingly significant.

For manufacturers and engineers in the electric motor industry, embracing the benefits of VPI technology is a step towards innovation and excellence. To learn more about how VPI can enhance your motor designs, connect with industry experts and explore the potential of this transformative technology.